Essential details

CAS No : 9003-07-0

Other Names: POLYPROPYLENE

MF: C22H42O3

EINECS No : 202-316-6

Place of Origin: India

Type: Synthetic Fibers, Synthetic Resin And Plastics, Synthetic Rubbers

Brand Name: The Indian chemical

Purity: 99%

Product name: 3 5-Dimethylphenol

Appearance: white powder

MW: 354.56708

Sample: yes

About Polypropylene

Polypropylene (PP), a polymer prepared catalytically from propylene which differs from HDPE by having an isostatic replacement of a hydrogen atom by a methyl group on alternate carbon atoms in the main chain. Although largely unreactive chemically the presence of the methyl groups makes Polypropylene slightly more susceptible to attack by strong oxidizing agents than HDPE. A major advantage is Polypropylene’s higher temperature resistance, which makes PP particularly suitable for items such as trays, funnels, pails, bottles, carboys and instrument jars that have to be sterilized frequently for use in a clinical environment. Polypropylene is a translucent material with excellent mechanical properties and it has gradually replaced the polyethylenes for many purposes.

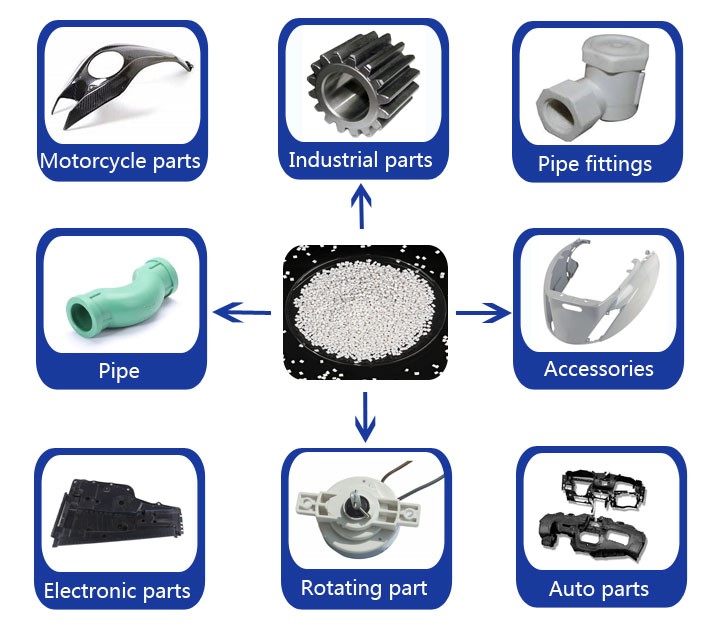

Applications

• The raw material for manufacturing tailgate, fenders, blower, fan cover, pump housing, valve body, gear, seal plate, flanges, fittings, instrumentation housing, power tools, microwave ovens, copiers, Electrical receptacle plates, the outside box of insurance lines ,etc

• Polypropylene is a kind of thermoplastic synthetic resin with excellent performance, which is a colorless and translucent thermoplastic lightweight general-purpose plastic. It has chemical resistance, heat resistance, electrical insulation, plasticity, good graft and composite functions, high strength mechanical properties and good high wear resistance.

① Machinery and automobile manufacturing parts

② Electronic and electrical industrial devices

③ Construction industry

④ Agriculture, fishery and food industry

• Textile Over wraps

• Garment paper Bags & Woven Fabrics

• Snack Food Packaging

• Furniture and House ware Industry

• Packaging Industry

• Textile Industry

• Stationery Industry

• Plastic parts and reusable containers of various types

Quick Facts

• Maximum Temperature : 275°F 135°C

• Minimum Temperature : 32°F 0°C

• Autoclavable : Yes

• Melting Point : 338°F 170°C

• Tensile Strength : 4,500 psi

• Hardness : R95

• UV Resistance : Poor

• Translucent

• Rigid